Aashish | 25th March | 4 min read

What is Fill rate/Fulfilment rate?

Fill rate is the percentage of retailer demand being fulfilled by the channel partner. In mathematical terms, it is the percentage of the ordered quantity that gets delivered to the retailer/customer.

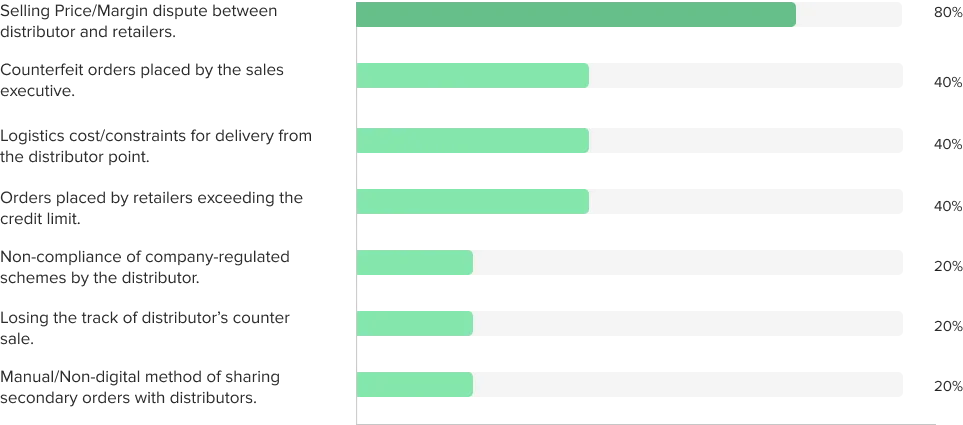

What are the causes of ineffective fill rates?

- Manual/Non-digital method of sharing secondary orders with distributors.

- Orders placed by retailers exceeding the credit limit.

- Losing the track of distributor’s counter sale.

- Selling Price/Margin dispute between distributor and retailers.

- Counterfeit orders placed by the sales executive.

- Non-compliance of company-regulated schemes by the distributor.

- Logistics cost/constraints for delivery from the distributor point.

Source : Survey Analysis – What are the causes of ineffective fill rates

Why is tracking fill rate important?

- Helps to measure the product penetration in the market segment.

- Helps to offer alternate products until the ordered product is available.

- Helps to determine the company’s retailer service level.

- Timely predictive order booking of distributor order.

Source : Survey Analysis – Why is tracking fill rate important?

What are the challenges in tracking fill rate?

- Usage of independent 3rd party billing software by the multi brand distributors.

- Distributor Counter sales data unavailability.

- Secondary order details are not being shared with the distributor digitally.

What are the possible mitigation/solutions?

1. Distributor Management System

Implementation of DMS can predominantly help the company to keep a track of Primary Orders and Delivery, Secondary Orders and Delivery, Distributor self sale, easy inventory monitoring, and improves regulatory compliance.

However, companies emerging newly in the market would channelise the sale via multi brand distributors. Distributor willingness, profitability and ROI of time is equally important for the adoption of the DMS system. In some cases, the company might be needing to regulate some incentives policy for the adherence of the process.

2. Recording Delivery status with digital proof/Goods received note by the field salesman

3. Live stock visibility of the distributor while placing any retailer order

Capturing the distributor’s floor stock and helping to keep an eye on the Supplier stock while taking secondary orders. Delivered Primary order placed by the distributor gets added up in the current stock and Delivered secondary orders get reduced from the current stock.

Live Stock = Current Stock + Primary Delivered Qty – Secondary Delivered Qty

In some cases, the company can restrict the secondary order taking incase if the supplier stock displays as NULL.

4. Restricting Retailer exceeding credit limits to place any order

Restrict placing any order for retailers, which have the current outstanding beyond the credit limit of the distributor.

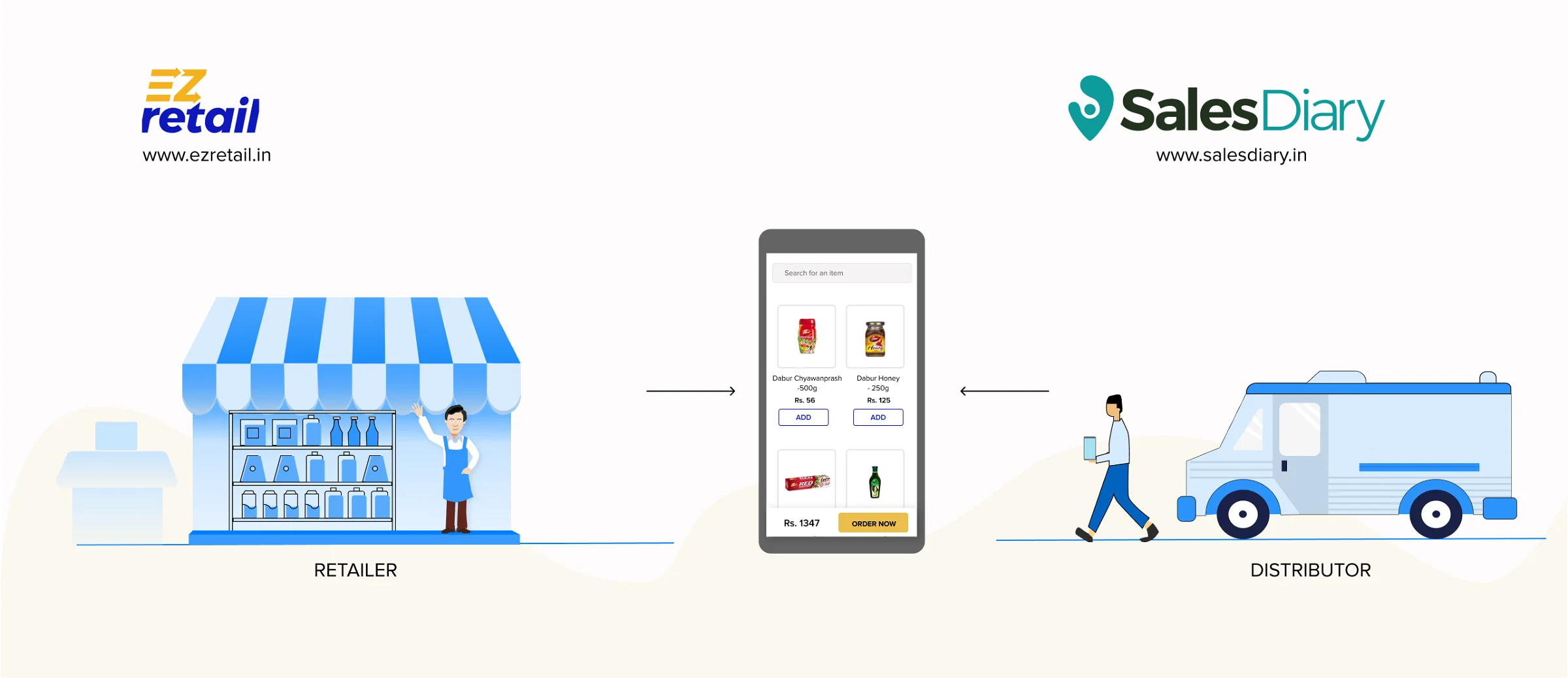

5. Instant Order Sharing with Distributors

Sharing the secondary sales orders instantly with the distributor via

email/Whatsapp/message. That helps the distributor to ensure that he has sufficient stock while delivering the order. In some ways, it helps the distributor to allow a sufficient amount of time before the dispatch and delivery.

Manual order sharing could be delayed due to the involvement of the executive in some other sales activities. Automation has its own discipline. 🙂

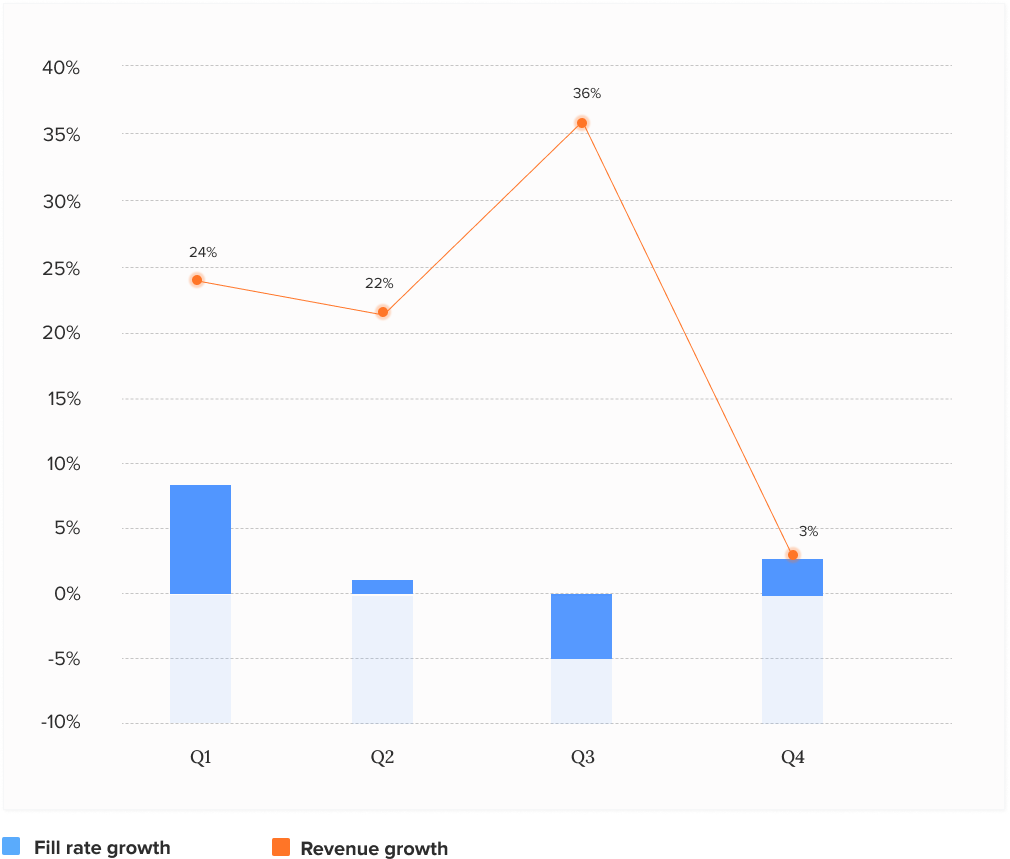

Impact Analysis

Source : Impact Analysis – Fill Rate Growth/Degrowth vs Revenue Growth

Source : Impact Analysis – Fill Rate Growth/Degrowth vs Revenue Growth

Observation: Fill rate growth is not always proportional to revenue growth. Even the slight increase (1%) in Fill rate in Q2 boosted the sales growth (by quantity) by 22%. Even in Q3, this has been observed that when the fill rate got dipped by 5%, the sales growth (by quantity) got increased by 36%.

Total Quarterly Primary sales increased from 20060944 units (Quarter 0) to 42923193 units (Quarter 4) with a Q-O-Q growth rate of 24%, 22%, 36%, and 3%.

Conclusion

Companies that monitor fill rates tend to have a higher opportunity to boost sales revenue. Monitoring the fill rate cannot be done only by implementing DMS but also by various features demonstrated above. It also helps the companies to understand the root cause behind low fill rate (in case) and mitigate the challenges.

How SalesDiary can help?

SalesDiary helps companies to implement a Distributor Management System. The system is agile to be integrated with any 3rd party billing software by exposing our APIs.

Since implementation of DMS has its own challenges:

- Distributor willingness to adopt a new system. It also includes a lack of capital and manpower.

- Multi-brand FMCG distributors can be reluctant to use different DMS for different brands.

- Struggle with unreliable electricity and internet connectivity especially in rural/semi-urban areas.

- Lack of interest to comply with the company policy. It can be related to product selling in defined territories or pricing as well.

It provides the solution to the company also by uploading the good received notes (GRN) while marking previous order delivery, setting up the credit limits of the outlets, and restricting sales executives to punch orders for retailers exceeding the credit limit.

SalesDiary also enables capturing the payment made by retailers by different modes like cash, cheque, UPI. It also helps sales executives to keep track of distributor stock while placing any orders. In case of counterfeit outlets (if created by any salesman), SalesDiary enables the supervisors to verify the outlets.