Waiting for goods on a dock in the dead of night and shivering like a leaf as the time ticking away, that’s how those hardy traders started their journey and are evolved into 21st century wholesale distributor with over 600,000 distributors in India, generating $6.5 trillion in annual revenue. According to recent studies the wholesale distribution contributes 6% to the nation’s overall GDP.

Time has proven that a good sales background alone will not contribute to success in the wholesale distribution. Operational skills are another factor that fills the space for a smooth flow of distribution process. The key here is to pick the next hot item, operating efficiently and transforming the goods that stocked quickly to fit into your pocket.

Following are the topics covered as part of this blog in order to understand distribution channel and how DMS can improve the efficiency, effectiveness and productivity of distribution of goods and services:

- Why distribution channel?

- Role of distribution channel

- Challenges faced in a distribution channel

- Using Distribution Management System (DMS) for distribution practices

Why distribution channel?

With the product in one place and the retailers scattered in many areas, there is a huge space between the manufacturer and the retailers. Think about a situation where a manufacturer has to deal with orders from over 14 million outlets and the retailers have to expect the delivery from different manufacturers where hundreds of trucks line up outside the outlet every day.

If the manufacturer goes for their own outlets, then they are placing an axe on customer convenience (customers have to visit multiple outlets to satisfy their needs) and also manufacturers will lose the focus from their primary responsibilities.

Hence distribution channel serves as an integral part in a supply chain in connecting between the manufacturer and retailers.

Role of distribution channel

A distribution channel fills the gap between the manufacturer and retailers. So, the products can be delivered from producers to retailers and thereby to the consumer at the right time.

A Distributor places the order to the manufacturer in advance, stocks the products in the distribution warehouse and on-demand the products are delivered straight away to the outlet. The process work as follows:

- Choose the product and place the order to the manufacturer

- Stock the products

- Implement the pricing strategy

- Categorise the retailers based on maximum product reach

- Setting up credit and schemes for retailers

- Take order from retailers and deliver the products

- Collection of outstanding payments

- Dealing with expired and damaged goods

- Monitoring the entire financial flow to ensure smooth business process

By placing the products at the right place at the right time with proper marketing strategy, a distributor meets the objective of the manufacturer and hence fills the gap between the manufacturer and the retailers.

Challenges faced in a distribution channel

In today’s world consumers become more demanding and their buying trends are tremendously changing within a short period. Let’s look into challenges faced by distributors in the modern world as elaborated below in the following sections: –

- Inability to forecast demand fluctuation

Distributors often end up with too many items that don’t sell and very few items that do. This fact confirms that the term “Higher Stocks and Periodic Shortage” is not a contradiction. Underestimating the product demand results in sales slip through your fingers due to the understock of products.And in another case, the distributor is left with overstock which results in the financial drain. The above scenario pinpoints the importance of forecasting demand fluctuation.

Information about demand fluctuation helps the distributors to identify the right products to stock up at the right time. The key here is to understand the demand fluctuation prior and plan accordingly.

So to predict demand fluctuation accurately, it’s necessary to gain insights about the factors that can cause fluctuation. Let’s say, for example, how seasonal changes account for change in consumer demand or how promotional strategies increase the demand of the product.

Understanding the factors which directly or indirectly influence the product demand helps to create the exact forecast model and thereby forecast the demand fluctuation accurately.This accuracy in information helps the distributor to make the right decision about the stock. But the bitter truth is that only 10% of distributors in India understand the importance of demand forecasting and the rest of them rely on the blanket rule such as “four weeks safety stock for everything”. So most of the distributors give least importance in organising the sales data and the information of day to day distribution process which serves as the fuel for designing forecast model.

- Longer replenishment gap

Due to the unstructured and inefficient routine process, most of the distributors constantly fail to determine the exact reorder-point for item replenishment. Since every product has a different demand rate and different replenishment delivery time for each manufacturer, the reorder-point calculation becomes more challenging for the distributor. For better understanding,

Consider that you sold 500 ‘X’ items for the last 120 days and it took 7,8,8,10,8 days respectively for the orders to get delivered.

To get the reorder point, calculation as follows:

Reorder point = (average daily usage * average delivery time) + safety stock

= ( 500/120 * (7+8+8+10+8)/5 ) + 6

= (4 * 8) + 6

= 38

So when the product level reaches 38, distributors should re-order the materials. Here the safety stock deals with the demand fluctuation.

When it comes to the real time scenario, the distributor has to calculate replenishment order schedules for hundreds of thousands of different products and keep track of their daily End of Day (EOD) stocks. Due to this unorganised routine practises in tracking day to day process, distributors often end up with inaccurate calculation and therefore, resulting in longer replenishment gap.

- Failure to keep on-time delivery promises

When analysing late pick-up or on-time delivery relationship, studies show that over 60% of load that picked up on time is delivered late. 11 shop outlets for every 1000 people in India indicates that the old age tactics of delivering goods will no longer serve the purpose. The major challenges faced are:

- Inefficiency to cover up maximum outlet

- Less capable of delivering goods based on priority

- Improper planning on outlet visit frequency

- Poor technology to track the delivery route

- Improper handling of unexpected situations like vehicle breakdown, driver on leave and so on.

Solving the above challenges can result in significant increase in efficiency of last-mile delivery. Hence, it’s important for industries to accurately define the process of delivery service for effective delivery plans. The key areas on which deliver managers must concentrate are:

- Plan route in such a way that delivery partners can cover maximum outlets in a single day and can optimise route based on the priority, frequency of visit and outstanding payment.

- Assign the task to a delivery partner who has previous experience in the planned route.

- Ensure that delivery partners follow the assigned route and maintain the schedule. Managers should enquire in case of deviation in location, timing and routes and hence corrective actions can be carried out.

- Lower profit margins

Running your business on the right profit margin is crucial for distributors. Being in the middle of the supply chain, distributors have the riskiest pricing policy. According to studies, over 75% of distributors in India are leaking from 1.0 to 3.0 margin points due to improper pricing methodologies.

To weigh the right margin, distributors have to consider not only the manufacturer cost but also the cost to transport goods such as tariff, managing the fleet of vehicles, cost to stock goods etc. In order to increase the profit margin, retailers try their best to purchase at the lowest cost possible from distributors. Therefore, the distributors lose out on their profit margin while ensuring to keep the inventory flowing consistently for better cash flows. Unfortunately, most of the time the distributors often end up with too high or too low pricing strategy. The major factors contribute to this cause are:

- Not considering the competition and competitors price

- Poor knowledge about target group and their ability to pay

- Lack of historical pricing data to compare pricing outcomes.

Hence to increase your profit margin, make sure that you follow the below mentioned practises:

- Use of dynamic pricing strategy provides greater visibility which helps to identify price leakage and profitability.

- Tailoring targeted schemes for retailers based on retailer performance, product categories, market preferences, and past data. This helps to maintain a healthy relationship with the retailers.

- Maintaining a centralised pricing management system so that distributors can get information about historical pricing data and can compare how the outcome will be for similar pricing policy.

- Longer claim turnaround time and fake claims

Distributors are searching in the dark when it comes to claim settlement process which results in longer claim turnaround time for retailers. This longer settlement process can lead to a fracture in terms of relationship with the retailers. Since retailers serve as a vital influencer in the overall market it’s important to maintain the relationship with them.

Often it becomes a tedious task for distributors to dive deep into the ocean of retailer claims and segregate it based on the accuracy of claims. This process becomes more of a headache when retailers come up with fake claims.

Consider a scenario where the distributor has to deal with 400 retailer outlets and hundreds of thousands of units in a month. There may be problems with the quantity of items in a unit (only 8 packs instead of 10 packs in a unit) or else few of the products are damaged or may be products about to expire and so on.

Managing the above scenario becomes tedious and often leads to longer settlement time due to some bad practises followed. This involves:

- Most of the time retailers submit claims after the period closure.

- Submission of claims by retailers without proper evidence which results in fake claims to get shuffled with real ones

- Extra time and cost need for processing hard copy claims.

- Delay in inspection team status update and incorrect claim calculation

Below we will discuss some important practises to be followed in managing distributors’ claims and settlement process:

- Define Service Level Agreement

Distributors should consider settling claims as a service. Hence a clearly defined service level agreement policy must be set with retailers. This includes claim turnaround time, deadline to raise the claim, accuracy of claims, percentage of claims with no evidence and so on. This helps retailers and distributors to clearly measure the efficiency claim service process and can justify the claim approval or rejection scenarios.

- Define integrated workflow to review claims

Distributors should ensure an integrated workflow to approve claim and settlement process. This helps the distributor to gather real time information and can lead to faster claim approval and settlement process.

- Ensure claims are calculated correctly

Distributors should ensure that claims are calculated correctly. With data integrity check and algorithmic calculations one can achieve accuracy.

Using Distribution Management System for Distribution purpose

Once you have understood what all best practises should be incorporated into your distribution process, you can take advantage of the right technology to drive the smooth flow of the distribution processes. Let’s look into how Sales Diary DMS app benefits the distribution process.

- Perfect Order Fulfilment

- Higher profit margin with dynamic pricing and targeted schemes

- Efficient claim approval and settlement process

- Perfect Order Fulfilment

The journey of a distributor starts with the mission of achieving perfect order fulfilment. But the distributor often fails to deliver the right product at the right place with the right quantity and in proper condition.

Here comes the importance of DMS. Due to the higher visibility offered by DMS in the distribution process, DMS can drive more perfect order rates to the distributors. Let’s explore one by one:

Real-time stock information

The first step towards a perfect order fulfilment is to place the order to the manufacturer at the right time. The key challenge is to set the accurate reorder-point for hundreds of thousands of different products which has different demand rate (based on retailer) and different replenishment delivery time (depends upon manufacturer).

Say, for an example, a unit of biscuit pack has a different demand rate compared to a unit of cosmetic pack. To be more precise, in case of biscuits, distributors have to replenish the outlet every week (may vary based on the shelf space) and at the same time for cosmetics it’s about once in two months. And the product delivery time varies among manufacturers.

Why setting the reorder point becomes a challenging factor?

Nearly 80% of the distributors don’t have real time information about their stock data. Most of the details are stored as hard copies which are scattered across different departments and the manual work is often prone to error. This results in distributors placing orders to the manufacturer at the wrong time which leads to either overstock or understock of the products.

How DMS overcome the challenge?

With DMS, a distributor can keep track of stock information such as:

The above information helps the distributor to get details to set the reorder point accurately and hence order can be placed at the right time by the distributor.

As we discussed above, setting the right reorder point helps the distributor to place the order at the right time and hence can stock up the right products. But one another factor which places a crack on setting reorder point is demand fluctuation. So, it’s important to consider safety stock while setting up a reorder point.

AI powered demand forecasting methodology helps you to deal with the change in consumer demand due to seasonal changes, demand increase as a result of product promotions and so on. Industries often failed to predict such scenarios and move forward with the same practices. This often ends up with higher loss.

Since DMS keeps track of all the sales data, it can easily identify how seasonal changes result in overall business process, the product categories or products in particular which saw an increase or decrease in demand specific to a particular region. In other cases, if the product demand increased as a result of organisation promotional activity then DMS can suggest the distributor if the organisation runs similar promotional activity to result in sudden demand in products.

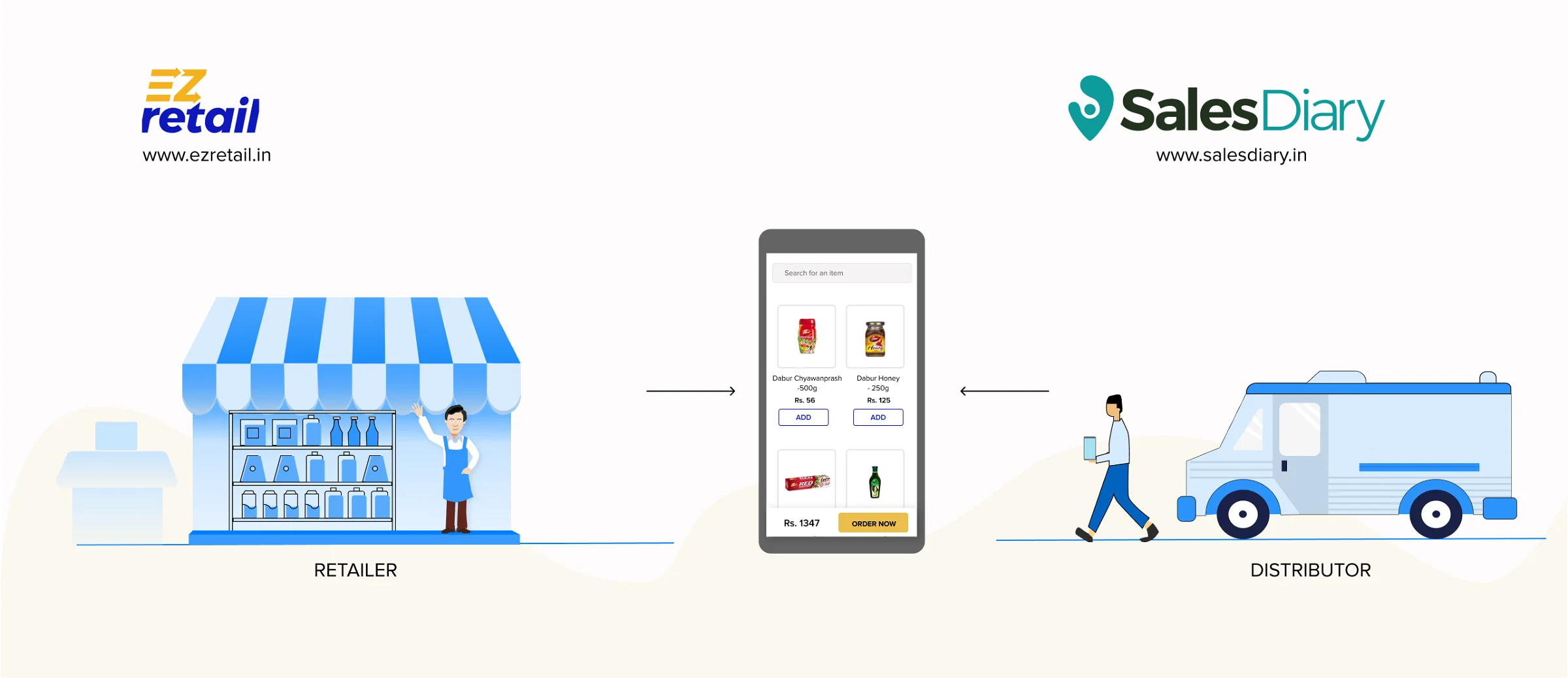

Once your inventory storage process is done, the next step is to take the orders from retailers, process the order and deliver the goods. According to the current scenario, the sales person will take the order from retailers and place it on distributor side, the distributor, hence, will process the order and make it ready for dispatch and then finally the delivery partner will deliver the goods to the retailer outlet.

Consider for an example, normally for a day, a salesperson has to visit 40 outlets to take orders to meet his deadline, but the question is how he chooses the outlet. Often sales people choose the outlet which is easier for them to cover irrespective of whether the outlet has higher demand or not. While they are doing so, they are delaying delivery in outlets that have higher demand and hence the order process is delayed and results in on-time delivery failure.

With DMS, distributors can get the accurate information of product flow for each retailer and their timely demand. This helps the distributor to easily classify the outlet based on priority and exactly capture the information such as frequency of visit required in a month, the exact time to send the sales person to take the order and so on.

Once the order is placed for retailers, next the distributor has to process the order and make it ready for dispatch and delivery. With over 20.32% of the increase in average order per day, the manual processing becomes a tedious task for the distributor.

DMS’ centralised sales data capture system ensures less paperwork and reduction in manpower to ensure faster order processing with fewer clicks. And also, the error free process ensures lesser order returns due to scenarios such as wrong address information, wrong invoice attached and so on.

And we move to the next part, which is the product delivery service. With DMS, you can assign the route to delivery partners who have prior experience in the route, suggest the optimized route which can cover up maximum outlet in a day based on priority and ensure that he sticks to the route assigned.

In addition to this you can handle unexpected situations like vehicle break down, driver on leave and can take necessary action within no time delay.

- Higher profit margins with dynamic pricing and targeted schemes

It’s crucial for distributors to set the right price for the products so that the price is not set too high (customer may look for alternative products) or too low ( results in revenue loss). From the above discussion you have already understood how DMS can reduce the overall cost of stocking goods and it’s transportation cost. Apart from these cost, two important factors that you should consider when pricing are:

- Retailer margin based on volume purchase

- Retailer margin to counter competitors

DMS’ dynamic pricing strategy can play a significant role in pricing decisions. It can weigh accurately how many customers are willing to pay for a product and its demand. Let’s consider an example of a beauty product, during the initial stage of product release distributor has to suffer less profit with the retailers. As soon as the product demand increases, distributors can negotiate more with retailers so that they can gain more profit. Here DMS can provide exact information about each stage of product such as the product flow in the market, how many customers are willing to pay and so on.

DMS dynamic pricing strategy is not all about increasing the margin, but sometimes you have to decrease it based on your competitors margin policy. If another distributor sells the same unit with a higher margin to the retailers, then your retailers will become their customers. With DMS you can track your competitors pricing policy and set the right pricing policy for not to run into loss.

Apart from dynamic pricing policy, setting targeted schemes which retailer benefits is necessary. According to the current process, distributors blindly distribute the schemes which may or may not benefit the retailers. Consider a scenario where you provide a scheme say, 3 pack free for buying 12 packs of a particular product. If the retailer doesn’t have the buying potential to buy 12 packs then obviously he rejects the scheme. Rather than if you provide a discount of x%, chances are high he may accept the scheme.

With DMS, you can segment the retailers based on their performance, or based on their buying potential,and so on. This helps the distributor to target the exact retailers for the scheme tailored and get the most value from each. And also with DMS you can tailor multiple schemes and track the scheme performance effectively and also can alter the scheme if required.

- Efficient claim approval and settlement process

Often retailers fail to approach the distributors on time for the complaints regarding the goods delivered. And in 90% of scenarios, retailers do not have proper evidence to justify their claim. This practice forces the distributor to categorise the claim as the fake one and reject the claim.

With DMS, you can set clearly defined service level agreement policy with the retailers. This includes claim turnaround time, deadline to raise the claim, accuracy of claims, percentage of claims with no evidence and so on. Such a practice ensures that retailer is aware about the claim policy in the beginning itself and they can take appropriate action

Since DMS offers an integrated workflow, makes claim approval and settlement process easier. Say, for an example, using DMS the respective person can submit the claim with proper evidence. With the integrated workflow system, distributors can see all the data related to the claim process and can avoid delay in gathering information from other departments.

And finally, data integrity check and algorithmic calculations provided by DMS ensures that claims are calculated correctly and hence results in accuracy.

Hence with DMS’ claim management system, you can save cost and at the same time maintain a healthy relationship with retailers.

Other than the above discussed points, DMS offers numerous benefits. Let’s bring all the benefits of DMS under one roof:

Order Management

- Accurate data driven order placing

- Proper replenishment gap

- Higher order fulfillment

- Increase in order frequency

- Less human interaction and paper-work

- Lower operational cost

- Fewer order returns

Inventory Management

- Perfect demand forecasting

- Real time stock information

- Data driven classification of inventory (based on product flow)

Pricing and Scheme Management

- Dynamic Pricing Strategy

- Customised Schemes

- Centralized pricing and scheme system

- Tailor multi scheme combination and alteration based on performance

- Track area wise performance

Dispatch and Delivery Management

- Efficient Route Planning and Optimisation

- Data driven Route Assignment

- Real time tracking and deviation alert

Payments and Outstanding Management

- Bulk Invoice Generation

- Track Outstanding Payment

- Set Automatic Reminders

Claim Management

- Agreement policy set up

- Efficient claim approval and settlement process

- Easiness in managing claim evidence

Tally Synchronized

- Centralized Data

- Easiness in import and export data

- Real time data Synchronization

Tax Compliance

- Invoice Management

- Simplified Tax Filling and Notifications

- Receivable tracking and alerts

BI Tools

- Easy report rebuilder

- Interactive dashboard elements

- Customisable

DMS impact on your ROI

| Revenue Increase | Cost Reduction | |

| ORDER MANAGEMENT | 99% faster order fulfilment 35% increase in order frequency | 91 % decrease in operational cost 99% decrease in order errors |

| INVENTORY MANAGEMENT | 80% increase in product availability Greater visibility of supply | 40% decrease in rationalized network cost 30% reduction in leveraged freight procurement 40% decrease in labour arbitrage 18% reduction in future capex spend |

| DELIVERY MANAGEMENT | 90% increase in on-time delivery70% increase in frequency of retail visit | 70% reduction in delivery cost |

The biggest challenge faced by the distribution sector today is poor distribution strategy despite the outstanding expertise in sales. This failure is mainly due to the lack of operational skills. With a proper Distribution management system, a sales expert can overcome their inefficiency in operational skills and can become a Samrat in the distributor sector.